Leading Supplier of China Paper Cup Inspection Machines

Discover Machinery's is a leading provider of high-quality paper cup inspection systems, trusted by businesses around the world. As one of the most reputable China paper cup inspection machine suppliers, we are committed to providing reliable, advanced technology that ensures the highest standards of quality control in paper cup production. Our paper cup inspection machine is designed to help manufacturers achieve consistent quality by thoroughly inspecting cups for defects, leaks, and dimensional accuracy, ensuring that only the best products reach the market.

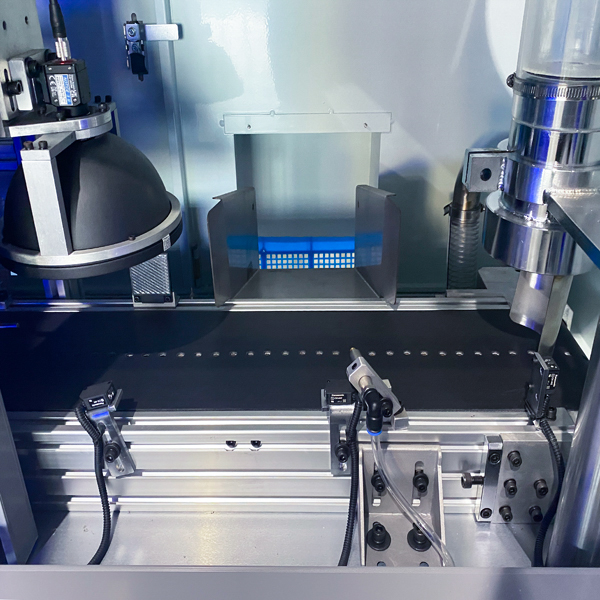

Conveying and positioning devices

It is composed of conveyor belts, rollers, etc., which are used to convey the paper cups through the detection area in turn at a certain speed and spacing to ensure that the paper cups can reach each detection position stably and accurately.Through the sensor, the paper cup is accurately positioned, and the paper cup is in a fixed position during image acquisition and detection, so as to improve the accuracy of detection.

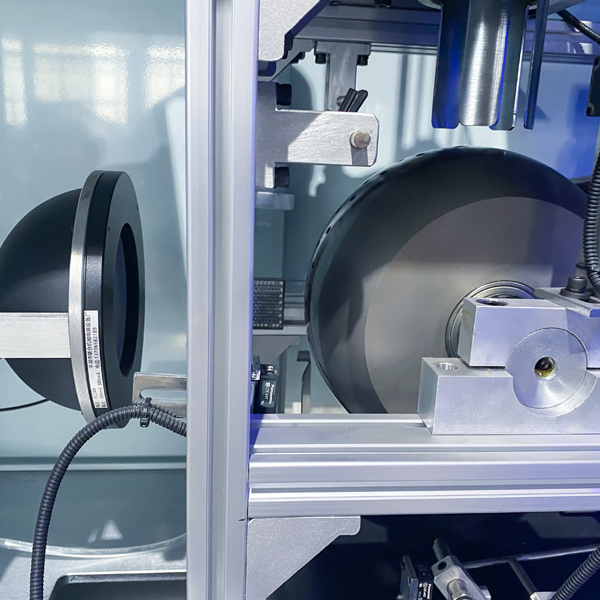

Image acquisition section

Equipped with a professional industrial camera, it is the core component of image acquisition, with the characteristics of high resolution and high frame rate, which can quickly and clearly capture the image information of the paper cup and provide clear image data for subsequent analysis.

Remove the mechanism part

It is composed of cylinders, electric push rods, etc., and when the unqualified paper cup is detected, the control system will issue an instruction to remove the unqualified paper cup from the conveyor belt through the actuator to ensure that the qualified product enters the next process.

Reliable Paper Cup Inspection Machines – Your Trusted China Paper Cup Inspection Machine Suppliers

Key Features of Our Paper Cup Inspection Machines

1. Advanced Defect Detection Technology

Our China paper cup inspection machine is equipped with state-of-the-art technology that automatically detects and removes defective cups during the production process. Whether it’s a flaw in the cup’s shape, size, or coating, the system quickly identifies issues, improving overall production efficiency and reducing waste.

2. High-Speed Operation for Maximum Efficiency

Designed for high-speed production lines, our inspection machines can handle a large volume of paper cups without sacrificing precision or speed. This ensures that manufacturers can maintain high output while keeping quality at the forefront.

3. Comprehensive Quality Control

With our paper cup inspection machine, every cup is checked for critical attributes such as wall thickness, bottom sealing, and overall structure. The machine performs a detailed inspection to ensure that each cup meets strict industry standards.

4. Easy-to-Use Interface and Intelligent Control

The intuitive control panel of the machine allows operators to quickly adjust settings and monitor performance in real time. The user-friendly interface enhances productivity, making it easier for operators to detect issues and manage the inspection process.

5. Accurate Dimension Measurement

Our machine includes precise measurement tools to ensure that each paper cup conforms to the specified size and dimensions. This feature is essential for businesses producing cups with specific volume requirements for beverages such as coffee, tea, and soft drinks.

6. Automated Sorting and Rejection System

The system is capable of automatically sorting out defective cups, rejecting them before they enter the packaging process. This minimizes the risk of defective products reaching the customer and ensures that only high-quality cups are packaged and shipped.

7. Customizable Settings for Diverse Production Needs

Our China paper cup inspection machine can be easily customized to meet the specific needs of your production line. Whether you are producing paper cups in different sizes, shapes, or with various coatings, the system adapts to different production requirements seamlessly.

8. Reliable and Durable Construction

Built with high-quality materials, our inspection machines are designed to withstand the rigors of continuous production. Their robust construction ensures long-lasting performance, reducing the need for frequent repairs and maintenance.

9. Efficient Integration with Existing Production Lines

The inspection machine is designed for easy integration into existing paper cup production lines. Its seamless operation helps maintain the speed and efficiency of your overall production process without causing interruptions.

10. Competitive Paper Cup Inspection Machine Quotation

At Discover Machinery's, we understand that cost-effectiveness is key for businesses. As China paper cup inspection machine suppliers, we offer competitive paper cup inspection machine quotation options, ensuring that you get the best value for your investment. We work closely with our clients to provide customized pricing based on their specific needs, helping them optimize their production lines within their budget.

Working Principle of the Paper Cup Inspection Machine

The China paper cup inspection machine operates based on advanced optical and sensor technology that enables high-precision defect detection and quality control. Here's how it works:

1. Cup Feeding and Positioning

The paper cups are automatically fed into the inspection machine using a conveyor system. The cups are positioned one by one for inspection, ensuring that each cup is individually examined for defects.

2. Optical Detection System

The core of the inspection process is the optical detection system, which uses high-resolution cameras or laser sensors to capture detailed images of each cup. These sensors are capable of detecting subtle defects such as deformities in shape, uneven bottom sealing, and imperfections in the paper coating.

3. Defect Identification

Using advanced algorithms, the machine compares the captured images against predefined quality standards. It scans for common defects such as holes, wrinkles, misalignments, and incorrect dimensions. The machine is programmed to identify even minor deviations from the ideal cup specifications.

4. Dimension Measurement

The machine measures key dimensions of each cup, such as height, diameter, and wall thickness. This ensures that every cup meets the required specifications for size and structural integrity, making it ideal for beverages that need specific cup sizes.

5. Sorting and Rejection Mechanism

Once a defect is detected or the cup fails to meet dimensional criteria, the machine activates an automatic sorting and rejection system. The defective cups are ejected from the production line, either by mechanical arms or air jets, to prevent them from proceeding further in the production process.

6. Real-Time Data Processing

The machine continuously processes data in real time, allowing operators to monitor the inspection process and identify any trends in defects. This feedback loop enables rapid adjustments to improve production quality and efficiency.

7. Output and Reporting

After the inspection and sorting process, the quality-approved cups are passed on for further packaging or shipping. The system generates detailed reports, which provide valuable insights into production quality and help manufacturers optimize their processes.

8. Integration with Production Line

The inspection machine is designed to work seamlessly with the existing production line. It is easily integrated with conveyors, cup stackers, and packaging systems, ensuring smooth workflow without interruptions.

Why Choose Discover Machinery's?

As a leading name among China paper cup inspection machine suppliers, Discover Machinery's provides world-class solutions designed to enhance the quality control process in paper cup manufacturing. Our machines are equipped with advanced features that ensure maximum efficiency and reliability.

By choosing Discover Machinery's, you benefit from our expertise, exceptional customer service, and commitment to innovation. Our paper cup inspection machine is an essential tool for any manufacturer looking to improve their production process and guarantee product quality.

For more information on our China paper cup inspection machine offerings or to request a paper cup inspection machine quotation, get in touch with Discover Machinery's today. Let us help you take your production line to the next level with precision, efficiency, and quality.

|

Inspecting speed |

240 pcs/min |

|

Inspecting position |

Top of Cup, inside wall and bottom,bottom of Cup |

|

Inspecting item |

Seam open, Wrong curling, leakage, damage, deformation |

|

Net weight |

600 kg |

|

Power supply |

3PH 380V |

|

Total power |

3.8KW |

|

Air consumption |

0.1cube/min |

|

Dimension of machine |

L1760*W660*H1700mm |

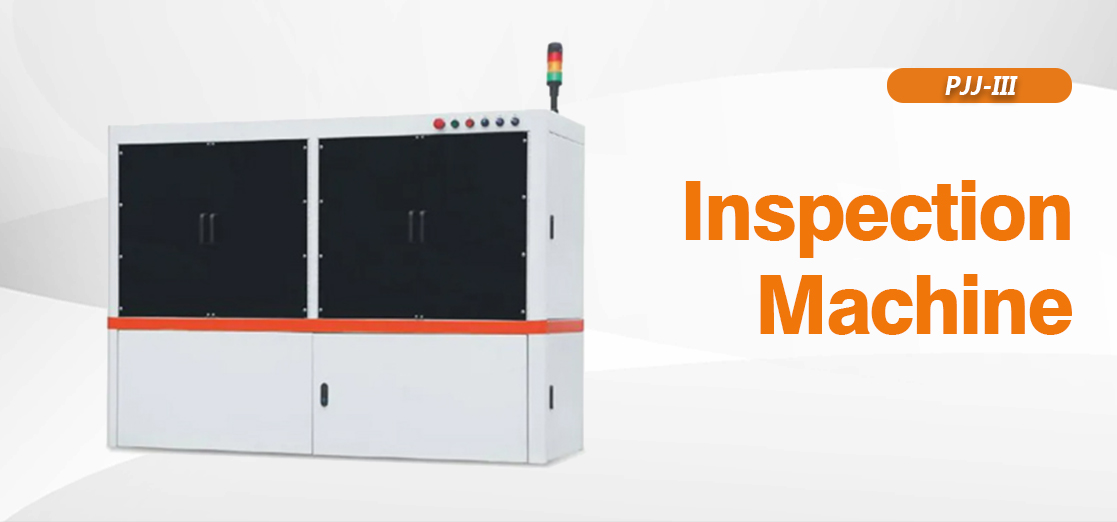

Intelligent Paper Cup/Container Paper Cup Inspection Machine

Intelligent Paper Cup/Container Paper Cup Inspection Machine

PJJ-III China Paper Cup Inspection Machine

PJJ-III China Paper Cup Inspection Machine