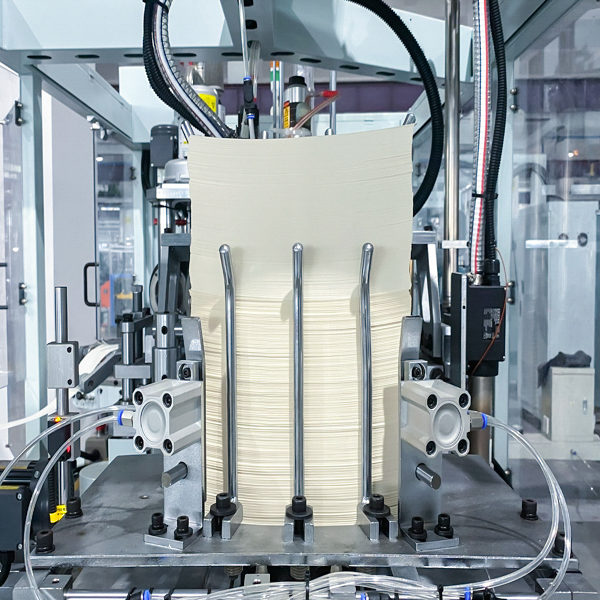

Discover Machinery's is proud to introduce the FWJ-Ⅳ Rectangular Paper Bowl Machine, an advanced solution designed for the efficient and high-quality production of rectangular paper bowls. As a leader in manufacturing and innovating paper bowl production technology, we are committed to providing our clients with state-of-the-art machinery that enhances productivity, ensures quality, and offers long-term reliability.

Fan-shaped piece feeding

The paper feeding mechanism discharges the fan-shaped sheet on the paper supply holder through the suction cup, and the conveying mechanism then sends the fan-shaped sheet to the next process.

Crimping mold

It is used to curl the upper mouth of the paper cup. The shape and size of the crimping die need to match the mouth of the paper cup, and by applying pressure, the paper is rolled smoothly. The quality of these parts directly affects the curling effect of the mouth of the paper cup, such as the flatness and tightness of the curling.

Forming molds and heating elements

The forming mold is one of the key components of the paper cup machine, which determines the shape and size of the paper cup. The molds have high-precision shapes and sizes and are able to withstand high temperatures and pressures. The heating element heats the paper during the cup forming process, softening the paper for a better fit to the mold.

High Efficiency and Versatility

Our Rectangular Paper Bowl Machine is engineered for versatility and high efficiency, capable of producing a wide range of rectangular paper bowls used in various industries, from foodservice packaging to take-out containers. With its cutting-edge technology, this machine streamlines the manufacturing process and ensures that each paper bowl is precisely formed with high standards of quality. The machine’s compact design allows it to be integrated seamlessly into existing production lines, offering a space-saving solution without compromising on performance.

Fully Automated Operation

At the core of the Rectangular Paper Bowl Forming Machine is its fully automated operation, which reduces manual labor and enhances the consistency of production. By automating key aspects of the manufacturing process, including paper feeding, forming, and ejection, the machine ensures that every paper bowl is produced to exact specifications. The automation also minimizes human error, leading to fewer production defects and less waste, making it an ideal choice for businesses looking to improve operational efficiency.

Intelligent Technology for Precision and Performance

Our Intelligent Rectangular Paper Bowl Forming Machine incorporates advanced smart technology, allowing it to self-regulate based on real-time data and performance analysis. This intelligent system not only improves the overall reliability of the machine but also helps optimize production speed and energy consumption. The system monitors critical parameters, such as pressure, temperature, and forming speed, and automatically adjusts them for optimal results. This smart feature ensures that every bowl produced meets stringent quality standards, minimizing defects and ensuring uniformity across large batches.

Flexibility and Customization

The FWJ-Ⅳ Rectangular Paper Bowl Machine offers exceptional flexibility with its ability to accommodate various paper types and thicknesses. This adaptability allows businesses to cater to different market demands, whether for lightweight bowls for snacks or durable containers for hot food. The machine can quickly switch between different bowl sizes, providing the necessary customization options for customers looking for tailored solutions. Its easy-to-use interface enables operators to set up and adjust production parameters effortlessly, making the machine accessible for both experienced and new users.

Reliability and Low Maintenance

In addition to its impressive technical features, the Rectangular Paper Bowl Machine is built for long-term reliability. Constructed with high-quality materials and designed for low maintenance, this machine ensures years of efficient operation. The robust build also contributes to minimizing downtime, enabling businesses to maximize their productivity and maintain high output levels. With Discover Machinery's comprehensive after-sales support, clients can rest assured that their machines will remain in peak condition throughout their lifespan.

Sustainability and Energy Efficiency

Our Intelligent Rectangular Paper Bowl Forming Machine also emphasizes environmental sustainability. By utilizing energy-efficient components and reducing material waste, it helps businesses lower their operational costs while contributing to a greener production process. The machine’s precise forming technology ensures minimal paper wastage, and its efficient energy consumption reduces its carbon footprint.

Conclusion

The FWJ-Ⅳ Rectangular Paper Bowl Machine is more than just a manufacturing tool; it is an investment in your business’s growth. Whether you're looking to scale up your production capabilities or improve the consistency of your products, this machine provides the perfect solution. Its intelligent features, versatility, and reliability make it the ideal choice for businesses in the foodservice, packaging, and take-out sectors.

At Discover Machinery's, we are committed to delivering solutions that help our customers stay competitive in a rapidly evolving industry. The FWJ-Ⅳ Rectangular Paper Bowl Machine is a testament to our dedication to innovation, quality, and customer satisfaction. If you’re looking for a machine that delivers high-speed production, exceptional quality, and long-term value, the FWJ-ⅣRectangular Paper Bowl Machine is the perfect choice.

|

Paper cup size |

Max top size is 170*120mm |

|

Production speed |

40-50 bowls per minute

|

|

Weight |

8000 kg |

|

Electrical |

3PH 380V |

|

Total power |

30 KW |

|

Air consumption |

0.6 cube/min |

|

Dimension of machine |

L3800*W1958*H1800mm |

|

Paper gram weight |

210-350gsm |

|

Paper type |

single PE or double PE |

FBJ-L Intelligent Rectangular Paper Bowl Forming Machine

FBJ-L Intelligent Rectangular Paper Bowl Forming Machine