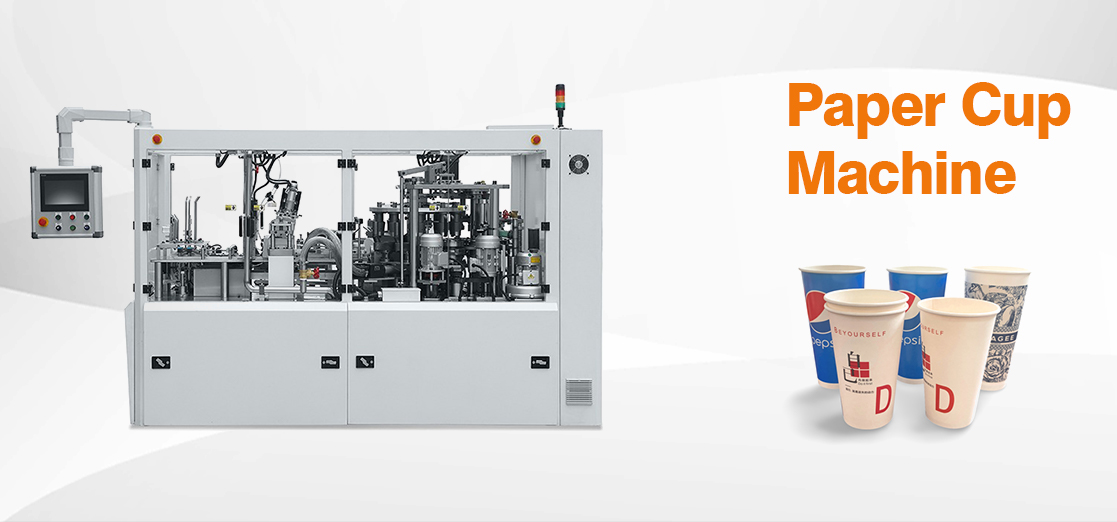

Production Speed 200 pcs/min Tea Cup Making Machine

High-Speed and Precision Engineering for Tea Cup Manufacturing

Discover Machinery's introduces the Production Speed 200 pcs/min Tea Cup Making Machine, a state-of-the-art solution designed for high-speed and precision-driven tea cup production. This advanced machine is engineered to meet the growing demands of the beverage packaging industry, ensuring efficiency, durability, and superior cup quality. Ideal for tea shops, beverage manufacturers, and large-scale production facilities, it offers unparalleled reliability and performance.

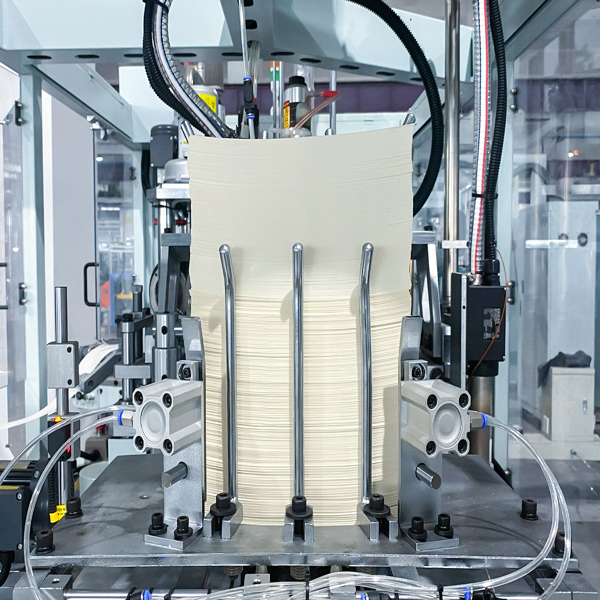

Fan-shaped piece feeding:

The paper feeding mechanism discharges the fan-shaped sheet on the paper supply holder through the suction cup, and the conveying mechanism then sends the fan-shaped sheet to the next process

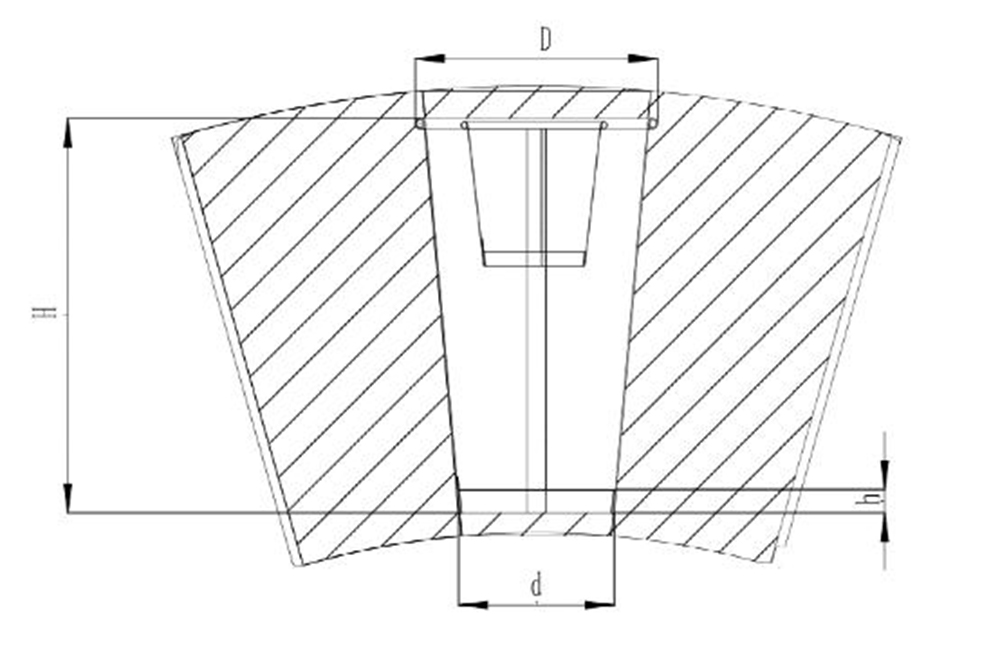

Crimping mold

It is used to curl the upper mouth of the paper cup. The shape and size of the crimping die need to match the mouth of the paper cup, and by applying pressure, the paper is rolled smoothly. The quality of these parts directly affects the curling effect of the mouth of the paper cup, such as the flatness and tightness of the curling.

Forming molds and heating elements

The forming mold is one of the key components of the paper cup machine, which determines the shape and size of the paper cup. The molds have high-precision shapes and sizes and are able to withstand high temperatures and pressures. The heating element heats the paper during the cup forming process, softening the paper for a better fit to the mold.

Key Features of the Production Speed 200 pcs/min Tea Cup Making Machine

1. High-Speed and Efficient Production

This tea cup making machine operates at an impressive speed of 200 cups per minute, significantly increasing output while maintaining exceptional quality. Its automated production process ensures seamless operation, reducing manual labor and maximizing productivity.

2. Fully Automatic Operation

Designed as a fully automatic paper cup making machine, it integrates advanced automation technology for paper feeding, bottom sealing, side sealing, cup curling, and stacking. This high level of automation minimizes human intervention, ensuring consistent cup quality and reducing production errors.

3. Robust and Durable Construction

Manufactured with high-quality materials, this machine offers long-lasting durability and stability. Its reinforced frame and precision-engineered components enhance operational efficiency, making it a cost-effective investment for long-term use.

4. Versatile Paper Compatibility

The machine supports both single and double PE-coated paper, making it suitable for hot and cold beverage cups. This flexibility allows manufacturers to expand their product range without requiring additional equipment.

5. High-Quality Cup Forming and Sealing

With advanced heating and sealing technology, the machine ensures strong side and bottom sealing, preventing leaks and enhancing cup durability. This feature is particularly beneficial for tea cups, which require a sturdy design to withstand hot liquids.

6. Energy-Efficient Performance

The fully automatic paper cup making machine is designed to optimize energy consumption, reducing operational costs while maintaining high output. Its intelligent energy management system ensures efficient power usage without compromising performance.

7. Intelligent Monitoring and Safety Features

A built-in real-time monitoring system detects faults and automatically stops the machine when necessary, preventing damage and ensuring operational safety. This self-diagnostic function helps operators quickly identify and resolve issues, minimizing downtime.

8. User-Friendly Control System

The intuitive touchscreen control panel allows operators to adjust settings, monitor production rates, and optimize performance easily. This streamlined interface simplifies operation and requires minimal training.

9. Consistent Cup Quality and Precision Engineering

By maintaining precise temperature, pressure, and forming controls, the machine ensures uniform cup thickness, strong bonding, and a smooth rim finish. This guarantees high-quality production for every batch of tea cups.

10. Low Maintenance and Cost-Effective Operation

Engineered for long-term efficiency, this disposable paper cup making machine requires minimal maintenance, reducing overall operational costs. Easily accessible components simplify routine servicing and part replacements.

Why Choose Discover Machinery's?

As a trusted industry leader, Discover Machinery's specializes in designing and manufacturing high-performance tea cup making machine solutions that meet international standards. Our advanced fully automatic paper cup making machine technology ensures optimal efficiency, precision, and reliability for businesses looking to enhance their cup production capabilities.

With a commitment to innovation and customer satisfaction, we provide exceptional after-sales support, including technical assistance, spare parts supply, and troubleshooting guidance. Our goal is to help businesses achieve seamless, high-speed production with minimal downtime.

For companies seeking a disposable paper cup making machine that combines speed, durability, and cutting-edge automation, the Production Speed 200 pcs/min Tea Cup Making Machine is the ultimate choice. Contact us today to learn more about how this machine can elevate your production efficiency and keep your business ahead in the competitive paper cup industry.

|

Paper cup size |

2-16 oz |

|

Paper cup dimension |

(D)φ40-90mm (H)40-135mm

(d)φ30-75mm (h)3-15mm

|

|

Production speed |

140-160pcs/min

8,400-9,600pcs/hour

67,200-76,800pcs/8 hours

|

|

Weight |

5,300 kg |

|

Electrical |

3PH 380V |

|

Total power |

21KW |

|

Air consumption |

0.4cube/min |

|

Dimension of machine |

L2750*W1300*H1800mm |

|

Paper gram weight |

210-350gsm |

|

Paper type |

single PE or double PE |

KSJ-160 Paper Tea Cup Making Machine

KSJ-160 Paper Tea Cup Making Machine

ZSJ-III Automatic Paper Cup Making Machine Manufacturers

ZSJ-III Automatic Paper Cup Making Machine Manufacturers

ZSJ-Ⅲ 16oz Paper Cup Machine Manufacturer

ZSJ-Ⅲ 16oz Paper Cup Machine Manufacturer