ZWJ-Ⅲ-L 22oz Paper Cup Making Machine

High-Performance Solution for Large-Size Paper Cup Production

Discover Machinery's proudly presents the ZWJ-Ⅲ-L 22oz Paper Cup Making Machine, a high-speed and precision-engineered solution designed for manufacturing large-capacity paper cups. This machine is ideal for producing cups for cold drinks, soft drinks, and specialty beverages, meeting the growing demand for high-quality, durable paper cups. With its advanced automation and intelligent control system, the ZWJ-Ⅲ-L ensures smooth, efficient, and high-volume production, making it a valuable investment for businesses in the beverage packaging industry.

Bowl mouth forming

The bowl mouth forming process in a paper bowl making machine shapes and strengthens the rim, ensuring durability, a smooth finish, and a secure structure for stacking and lid sealing.

Forming process

The forming process in a paper bowl making machine involves feeding paper, heating, molding, and sealing to create durable, well-shaped bowls with precise edges, ensuring high efficiency and consistency.

Paper unloading device

The paper unloading device in a paper bowl making machine efficiently removes finished bowls from the mold, ensuring smooth operation, reducing manual handling, and enhancing production speed and efficiency.

Key Features of the ZWJ-Ⅲ-L 22oz Paper Cup Making Machine

1.Efficient and High-Speed Production

This paper cup making machine operates with advanced automation, ensuring smooth and fast production of 22oz paper cups while maintaining superior quality. Its high-speed capabilities allow manufacturers to meet increasing market demands without compromising efficiency.

2.Advanced Cup Forming Technology

The machine is equipped with a precision-engineered cup forming machine that guarantees consistent shaping, strong side sealing, and a smooth rim for enhanced durability and usability. The precise cup molding process ensures every cup is uniform in size and strength, making it ideal for high-volume production.

3.Robust and Durable Design

Built with high-quality materials, the machine ensures long-term reliability with minimal maintenance requirements, reducing downtime and increasing operational efficiency. The reinforced mechanical components enhance stability and longevity, even under continuous operation.

4.Versatile Paper Compatibility

Capable of handling both single and double PE-coated paper, this coffee cup making machine is suitable for a wide range of beverage applications, including hot and cold drinks. This flexibility allows manufacturers to expand their product offerings without needing additional equipment.

5.Automated Production Process

Featuring a fully automatic workflow from paper feeding to bottom sealing, curling, and cup collection, this system enhances efficiency and reduces labor costs. The high level of automation reduces human error, ensuring consistently high-quality output.

6.Energy-Saving Performance

Optimized for energy efficiency, this machine minimizes power consumption while maintaining a high output, making it an eco-friendly choice for manufacturers. The intelligent energy-saving system adjusts power usage based on production speed, reducing unnecessary energy waste.

7.Intelligent Monitoring System

With real-time fault detection and automatic shutdown features, the system ensures operational safety and reduces the risk of production errors. The built-in self-diagnostic function helps operators quickly identify and resolve issues, minimizing downtime.

8.User-Friendly Control Panel

The intuitive touchscreen interface allows operators to easily adjust settings, monitor production speed, and optimize performance without complex training. The control panel provides real-time data feedback, enabling efficient machine management.

9.Consistent Cup Quality

By maintaining precise temperature and pressure controls, the machine guarantees uniform cup thickness, secure bonding, and a flawless finish. The machine’s precision heating system ensures proper paper sealing, preventing leaks and defects.

10.Low Maintenance Requirements

Designed with durability and efficiency in mind, this paper cup making machine requires minimal maintenance, reducing overall operational costs. The easily accessible components simplify routine inspections and part replacements.

Why Choose Discover Machinery's?

As a leading manufacturer in the industry, Discover Machinery's specializes in developing high-performance paper cup making machine solutions tailored to various business needs. Our coffee cup making machine is designed to maximize production efficiency, minimize operational costs, and ensure the highest product quality. With a commitment to innovation and excellence, we provide advanced cup forming machine technology that meets international manufacturing standards.

Our dedicated customer support team offers comprehensive after-sales services, including technical guidance, spare parts supply, and troubleshooting assistance. We are committed to helping our clients achieve long-term success by delivering cutting-edge manufacturing solutions that improve productivity and profitability.

For businesses seeking a reliable, high-speed, and efficient solution, the ZWJ-Ⅲ-L 22oz Paper Cup Making Machine is the perfect choice. Contact us today to learn more about how this cutting-edge machine can enhance your production capabilities and keep your business ahead in the competitive paper cup industry.

|

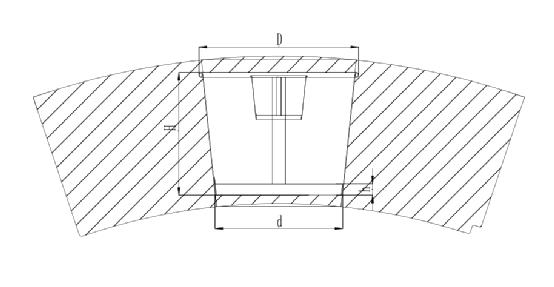

Paper bowl size |

5-24 oz |

|

Paper bowl dimension |

D)φ90-115mm (H)40-180mm

(d)φ30-100mm (h)3-15mm

|

|

Production speed |

75-85pcs/min

4,500-5,100pcs/hour

36,000-40.800pcs/8hours

|

|

Weight |

3,700 kg |

|

Electrical |

3PH 380V |

|

Total power |

20.6KW |

|

Air consumption |

0.4cube/min |

|

Dimension of machine |

L2715*W2025*H1600mm |

|

Paper gram weight |

210-350gsm |

|

Paper type |

single PE or double PE |

KSJ-160 Paper Tea Cup Making Machine

KSJ-160 Paper Tea Cup Making Machine

ZSJ-III Automatic Paper Cup Making Machine Manufacturers

ZSJ-III Automatic Paper Cup Making Machine Manufacturers

ZSJ-Ⅲ 16oz Paper Cup Machine Manufacturer

ZSJ-Ⅲ 16oz Paper Cup Machine Manufacturer